Difference between revisions of "Talk:Servomechanisms (aka "Servos")"

m |

m |

||

| (27 intermediate revisions by the same user not shown) | |||

| Line 1: | Line 1: | ||

| − | The E-2? Robot project has adopted two | + | The E-2? Robot project has currently adopted two types of servomechanisms to drive its mechanical parts. |

| − | |||

| − | '''HS-645MG''' | + | '''HS-645MG''': |

this is the smaller one, with 90° shaft rotation (in the simplest configuration) or 180° with a special RC controller or using Hitec's servo stretcher. | this is the smaller one, with 90° shaft rotation (in the simplest configuration) or 180° with a special RC controller or using Hitec's servo stretcher. | ||

| + | [[Image:HITEC_HS-645MG.jpg]] | ||

| + | | ||

| + | [[Image:Servo_Hardware_Horns.gif]]<br> | ||

| − | '''HS-785HB''' | + | '''HS-785HB''': |

this is the bigger one, with shaft angular movement ranging from (-360°*2.5) to (-360°*2.5), two complete turns and a half per direction. | this is the bigger one, with shaft angular movement ranging from (-360°*2.5) to (-360°*2.5), two complete turns and a half per direction. | ||

| + | [[Image:HS-785HB_with_drum.jpg]] | ||

| + | | ||

| + | [[Image:HITEC_HS-785HB.jpg]]<br> | ||

| − | Here we describe how we've tried to assess the continuous torque of | + | Here we describe how we've tried to assess the ''continuous torque'' of HS-645MG. |

| − | Hitech gives a generic torque specification on the box of their servos and on their internet site | + | Hitech gives a generic torque specification on the box of their servos and on their internet site - contacted by us, one of Hitec's service managers wrote that the torque on the spec denotes the "stall torque" and to assume its 80 percent as continuous torque. |

| − | In order to test our | + | ''In order to test our servos we have done the following:'' |

| − | + | ||

| − | + | <ul><li>opened the case of our servo and fitted a thermocouple near the circuitry, then closed it back | |

| − | + | </li><li> | |

| − | + | mounted a horn (the red one in the image) on the shaft, then attached a wire at a known distance from the horn's center, using the farthest hole available on the horn. The wire's end will be used to apply a force, which, using the horn as the lever's arm, will create the desired moment on the shaft | |

| + | </li><li> | ||

| + | arranged some objects (like bottles filled with water, wired together) with adjustable mass: their weight multiplied by the length of the winch's arm (19mm in our case) will equal the tested torque.</li> | ||

| + | <li> | ||

| + | found a convenient place, like a table, to support in keeping the servo still during the test, while allowing enough vertical room below of it (for the objects that provide the force)</li> | ||

| + | </ul> | ||

| + | ''And we have assumed that:'' | ||

| + | <ul><li>we can apply a moment using a single force at an arm's end, thereby obtaining something different from a "pure" torque: our force induces rotation and translation, while a pure torque (a couple) causes only rotation. | ||

| + | </li><li> | ||

| + | in the context of our robot's operation, a mere 10 minute's test time should be enough to characterize the tested torque as "continuous". In fact we may prevent prolonged stress for our servos via behavior rules - the basis for this is that we see no reason to keep the body in a completely bent configuration for more than a minute or two (OK?). | ||

| + | </li></ul> | ||

| − | + | So we've started our test, using Hitec's specification of continuous torque (76.80 kgf*mm) as initial guess, and we've seen the measured temperature rising rapidly from 35° to 40° in the first three or four minutes of our test, so we've decided to abort this test, guessing that the actual temperature in the machinery/circuitry of our servo could be higher. | |

| − | We've | + | We've prepared a second test run with a lower torque (59.19 kgf*mm) and this time we've reached the same high temperature in 10 minutes, thereby deciding to adopt this second value as a better estimate of the "continuous" torque. |

| − | We've | + | We've set up our servo for a new test run: this time we're using a lower torque, annotating the temperature, and trying to rotate the shaft at the end of our test, to see the difference in movement - the results: |

| + | |||

| + | Torque applied: 59.19 kgf*mm<br> | ||

| + | Final temperature: 48 °C<br> | ||

| + | Motion degradation: significantly slower, but still effective to rotate and lift the weight<br> | ||

| + | |||

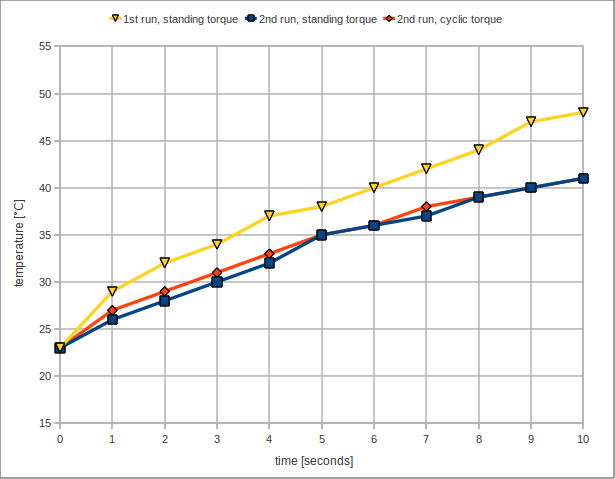

| + | On the temperature chart (below, yellow line) we see that the servo heating looks normal only during the first five minutes, and since the final motion degradation in not acceptable, we decide to reduce the applied torque. | ||

| + | |||

| + | At the same time we redefine our testing procedure: | ||

| + | |||

| + | <ul><li>we want to use something stable for keeping the servo in place during our test, like a bench vice - so we mount our servo on its support (the one in use on E-2?), which we have previously attached on a Item 5 series profile. | ||

| + | This way we can use the bench vice of AIRLab to make the Item profile and everything stand still (instead of holding it manually on the table's edge) so we can focus on the testing activity</li> | ||

| + | <li>we use a lower torque by reducing the arm's length, and we adopt a new horn (the one in the image) which does not interfere with the cord that holds the weight, during shaft operations<br>[[Image:Servo_arm_148SH.jpg]]<br> </li> | ||

| + | <li>we operate the servo during the first test like in the previous run: making the arm stand still in the horizontal position, to achieve the maximum torque, then at the end of the test we go down and up again</li> | ||

| + | <li>we do the second test applying continuously this pattern of movements: | ||

| + | <ul> | ||

| + | <li>5 up and down cycles, normal speed: period of approx. 3 seconds (2 second to go up, 1 second down)</li> | ||

| + | <li>1 up and down cycle, quick</li> | ||

| + | <li>10 seconds standing in a low stress position</li></ul> | ||

| + | </li></ul> | ||

| + | |||

| + | We've had these same results for both the test runs: | ||

| + | |||

| + | Torque applied: '''46.73 kgf*mm'''<br> | ||

| + | Final temperature: 41 °C<br> | ||

| + | Motion degradation: reasonably slower<br> | ||

| + | |||

| + | We can accept this new estimate, given the premises above regarding the continuous torque, and it's interesting to point out that this torque equals the 49% of the stall torque declared on the box of the servo. | ||

| + | |||

| + | [[Image:Servo_test_runs.png]] | ||

Latest revision as of 14:19, 27 January 2011

The E-2? Robot project has currently adopted two types of servomechanisms to drive its mechanical parts.

HS-645MG:

this is the smaller one, with 90° shaft rotation (in the simplest configuration) or 180° with a special RC controller or using Hitec's servo stretcher.

HS-785HB: this is the bigger one, with shaft angular movement ranging from (-360°*2.5) to (-360°*2.5), two complete turns and a half per direction.

Here we describe how we've tried to assess the continuous torque of HS-645MG.

Hitech gives a generic torque specification on the box of their servos and on their internet site - contacted by us, one of Hitec's service managers wrote that the torque on the spec denotes the "stall torque" and to assume its 80 percent as continuous torque.

In order to test our servos we have done the following:

- opened the case of our servo and fitted a thermocouple near the circuitry, then closed it back

-

mounted a horn (the red one in the image) on the shaft, then attached a wire at a known distance from the horn's center, using the farthest hole available on the horn. The wire's end will be used to apply a force, which, using the horn as the lever's arm, will create the desired moment on the shaft

- arranged some objects (like bottles filled with water, wired together) with adjustable mass: their weight multiplied by the length of the winch's arm (19mm in our case) will equal the tested torque.

- found a convenient place, like a table, to support in keeping the servo still during the test, while allowing enough vertical room below of it (for the objects that provide the force)

And we have assumed that:

- we can apply a moment using a single force at an arm's end, thereby obtaining something different from a "pure" torque: our force induces rotation and translation, while a pure torque (a couple) causes only rotation.

-

in the context of our robot's operation, a mere 10 minute's test time should be enough to characterize the tested torque as "continuous". In fact we may prevent prolonged stress for our servos via behavior rules - the basis for this is that we see no reason to keep the body in a completely bent configuration for more than a minute or two (OK?).

So we've started our test, using Hitec's specification of continuous torque (76.80 kgf*mm) as initial guess, and we've seen the measured temperature rising rapidly from 35° to 40° in the first three or four minutes of our test, so we've decided to abort this test, guessing that the actual temperature in the machinery/circuitry of our servo could be higher.

We've prepared a second test run with a lower torque (59.19 kgf*mm) and this time we've reached the same high temperature in 10 minutes, thereby deciding to adopt this second value as a better estimate of the "continuous" torque.

We've set up our servo for a new test run: this time we're using a lower torque, annotating the temperature, and trying to rotate the shaft at the end of our test, to see the difference in movement - the results:

Torque applied: 59.19 kgf*mm

Final temperature: 48 °C

Motion degradation: significantly slower, but still effective to rotate and lift the weight

On the temperature chart (below, yellow line) we see that the servo heating looks normal only during the first five minutes, and since the final motion degradation in not acceptable, we decide to reduce the applied torque.

At the same time we redefine our testing procedure:

- we want to use something stable for keeping the servo in place during our test, like a bench vice - so we mount our servo on its support (the one in use on E-2?), which we have previously attached on a Item 5 series profile. This way we can use the bench vice of AIRLab to make the Item profile and everything stand still (instead of holding it manually on the table's edge) so we can focus on the testing activity

- we use a lower torque by reducing the arm's length, and we adopt a new horn (the one in the image) which does not interfere with the cord that holds the weight, during shaft operations

- we operate the servo during the first test like in the previous run: making the arm stand still in the horizontal position, to achieve the maximum torque, then at the end of the test we go down and up again

- we do the second test applying continuously this pattern of movements:

- 5 up and down cycles, normal speed: period of approx. 3 seconds (2 second to go up, 1 second down)

- 1 up and down cycle, quick

- 10 seconds standing in a low stress position

We've had these same results for both the test runs:

Torque applied: 46.73 kgf*mm

Final temperature: 41 °C

Motion degradation: reasonably slower

We can accept this new estimate, given the premises above regarding the continuous torque, and it's interesting to point out that this torque equals the 49% of the stall torque declared on the box of the servo.