Difference between revisions of "Making rubber models"

| Line 30: | Line 30: | ||

[[Image:P6231682.JPG]] | [[Image:P6231682.JPG]] | ||

| − | Then i used Feather | + | Then i used Feather Lite that is a heavily filled low-density urethane casting resin |

| + | |||

| + | [[Image:P6231683.JPG]] | ||

| + | |||

| + | First you have to roughly mix each compound separately and then you can mix together the two compound 1:1 and put htem into the stamp | ||

| + | |||

| + | [[Image:P6231684.JPG]] | ||

| + | |||

| + | In 8 minutest you will not be able to modify the form of the stamp an in 2h you can demold the stamp. Thi is the result: | ||

| + | |||

| + | [[Image:P6231685.JPG]] | ||

| + | |||

== Create a copy of the original object == | == Create a copy of the original object == | ||

Revision as of 10:31, 1 July 2008

A rubber model is useful when you are tring to create a prototype of an object that you are planning to build.

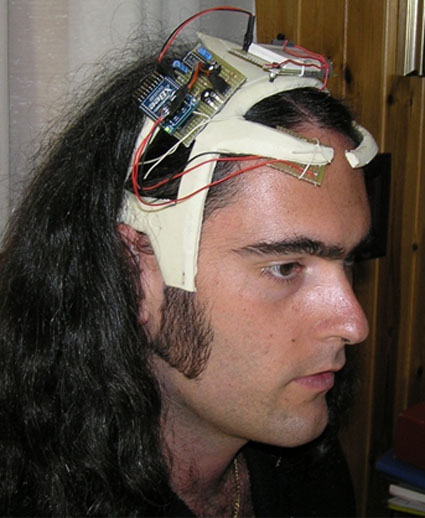

This is the object that will be created in this section

To build a model you need three main steps:

Having/Building the original object you want to replicate (POSITIVE)

The material with which you bel the positive can be wood, clay or wax.

Remember that whan you are using something different from wax, you have to apply a release agent in order to pull out the model from the stamp

Build the stamp that will used to replicate many times the object (NEGATIVE)

Now there is the interesting part. To build the stamp and the original object i have used some interesting products that can be found at smooth-on[1]. You can buy from the unique sellers in italy in Lissone:

Ferba, S.R.L. Via Goito 23 20035 Lissone Milano, Italia Tel: 390 392 143 022 Fax: 390 394 655 055 E-mail: erbadaniela(at)ferba(dot)it

The materials you can chose are very wide: You can have solid NEGATIVE and Rubber NEGATIVE or viceversa. The first one is my chioce since i need a rubber object.

I have first created a container for the model

Then i used Feather Lite that is a heavily filled low-density urethane casting resin

First you have to roughly mix each compound separately and then you can mix together the two compound 1:1 and put htem into the stamp

In 8 minutest you will not be able to modify the form of the stamp an in 2h you can demold the stamp. Thi is the result: