Difference between revisions of "Zoidberg II, powering robot fish"

MarcoPerri (Talk | contribs) (→Mechanical structure) |

MarcoPerri (Talk | contribs) (→Mechanical structure) |

||

| Line 66: | Line 66: | ||

<gallery> | <gallery> | ||

| − | + | Media:Forma_CATIA.jpg|First test body shape | |

Image:Modello_Poliuretano.jpg|Developed test body | Image:Modello_Poliuretano.jpg|Developed test body | ||

Image:Modello_Plastica.jpg|Propulsion test | Image:Modello_Plastica.jpg|Propulsion test | ||

Revision as of 16:31, 28 October 2009

Part 1: project profile

Project name

Zoidberg II, powering robot fish

Project short description

This project is aimed at designing, constructing and improving autonomous robot fish, starting from the ZOIDBERG project. It will be able to swim deeply in the water, to communicate and to orient in a free space thanks to several sensors mounted on-board.

Dates

Start date: 2008/11/01

End date: 2009/12/23

People involved

Project head(s)

Prof. Gini Giuseppina - User:GiuseppinaGini

Other Politecnico di Milano people

Ing. Paolo Belluco - User:PaoloBelluco

Students currently working on the project

Andrea Parolina - User:AndreaParolina

Dario Simontacchi - User:DarioSimontacchi

Marco Perri - User:MarcoPerri

Students who worked on the project in the past

Francesco Milli - User:FrancescoMilli

Maurizio Mercurio - User:MaurizioMercurio

Alessandro Nava - User:AlessandroNava

Laboratory work and risk analysis

Laboratory work for this project will be mainly performed at AIRLab/Lambrate. It will include significant amounts of mechanical work as well as of electrical and electronic activity. Potentially risky activities are the following:

Use of mechanical tools. Standard safety measures described in Safety norms will be followed. Use of soldering iron. Standard safety measures described in Safety norms will be followed. Use of high-voltage circuits. Special gloves and a current limiter will be used. Robot testing. Standard safety measures described in Safety norms will be followed.

Part 2: project description

The project is composed by:

- State of the art;

- Preliminary studies and sketches;

- Design notes and guidelines;

- Description and results of experiments;

State of the art

The work that mostly influenced the design of our robot is a lower-scale automaton realized by Z. Wang, G. Hang, J. Li, Y. Wang and K. Xiao, which is actuated with the same type of SMA that we used.

It is discussed in: A micro-robot fish with embedded SMA wire actuated flexible biomimetic fin

Preliminary part design

Mechanical structure

The design of the body has evolved into the current shape through many development steps, in response to the varying specifications of the on-board electronics, to changes in the manufacturing process of the hull, and for a better approach to the hydrostatic balance problem.

The first two images below represents the early proposed mostly flat design, and a step of the manufacturing of a "master" hull component in a modeling clay. The third image shows a simple prototype made of polyurethane foam, tethered to the tank for power supply. It can be noted the original configuration of the tail components, which were mounted in a horizontal fin arrangement with two parallel actuators.

- Forma CATIA.jpg

First test body shape

Electronics

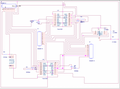

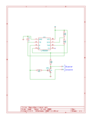

The first version of the on-board electronics was a two-boards arrangement. Due to problems and delays with the company responsible of the manufacturing of said boards, there are no working exemplars of this solution. In the meantime the circuit has been redesigned and simplified to fit a single board, and we put together a very simple intermittent circuit to carry the first autonomous tests (without the robot being tethered to the tank).

Below are shown, in order: the original schematics of the two boards, the schematic of the oscillator used for the first tests, based on a 555 chip, and the intermittent circuit assembled on a prototype board.

Videos of the actuator tests

Here are some clips, filmed during the first experiments trying to have a working actuator. The polymer and the electrodes are held in place by rough adhesive, and the power is supplied by an external generator. we are manually changing the polarity of the current going through the actuator.

Final design

(todo)

Tests and results

(todo)